Working in the winter months can be tricky, especially when the weather doesn’t cooperate. In some areas, we can experience a wide variety of weather in short times. It’s vital to be prepared for working in any weather condition our area can throw at us.

Ground Thawing

In the harsh winters we experience, working in the cold weather demands the use of ground thawing equipment. During winter, the ground itself doesn’t freeze, rather the moisture in the ground is what freezes, and ground thawing refers to the melting of the water in the ground. This is where ground thawing equipment such as that by Heat King or Thawzall can be employed. Water does a fantastic job of conducting heat, which allows warmth to efficiently transfer from the machine to the ground, and allows the ground to be thawed at the appropriate depth.

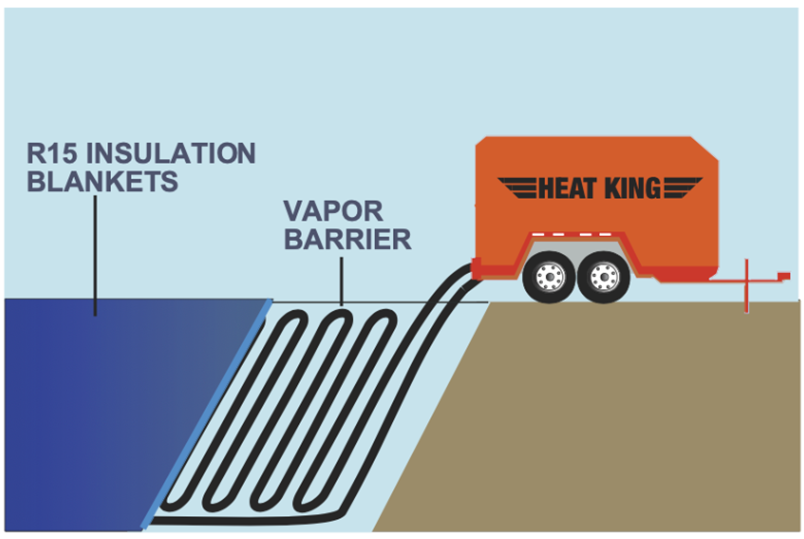

An important factor to consider is water vapor, which holds a great amount of heat but can easily be lost. When thawing ground areas, insulating the heating area instead of letting the vapor escape will further increase the effectiveness of the ground heating process. Using quality, multi-layered blankets to insulate the area can help the thaw progress much faster, as well as keeping the hoses clean when thawing is complete. If the vapor starts to vent and be released, the entire process can slow down, extending the time working in the unpleasant weather conditions.

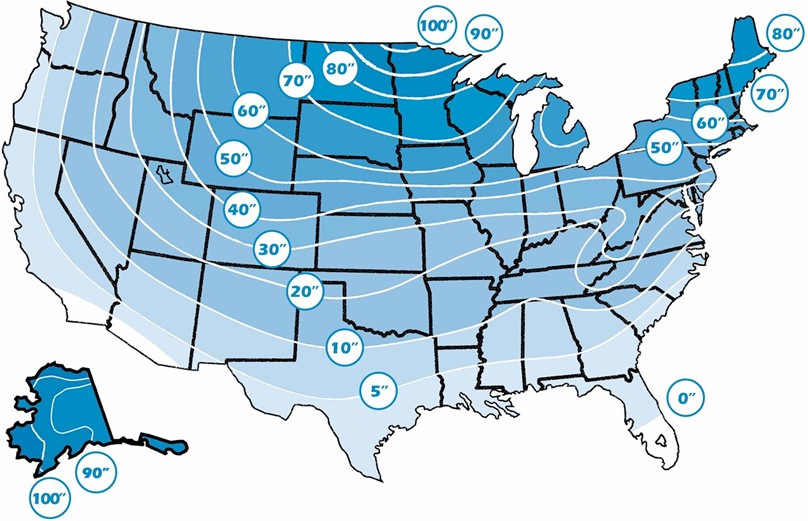

When starting a project, be sure to consider the frost depth, which will indicate the proper equipment  settings needed to thaw. The frost depth is determined regionally, consult this map for reference on where the frost depth will be for your area. Another key factor is the outdoor temperature, which can cause variations in the time needed to fully thaw the work area. Also consider the moisture content of the ground in the work area, too much or too little moisture can result in an unstable foundation, and a project that runs into serious delays.

settings needed to thaw. The frost depth is determined regionally, consult this map for reference on where the frost depth will be for your area. Another key factor is the outdoor temperature, which can cause variations in the time needed to fully thaw the work area. Also consider the moisture content of the ground in the work area, too much or too little moisture can result in an unstable foundation, and a project that runs into serious delays.

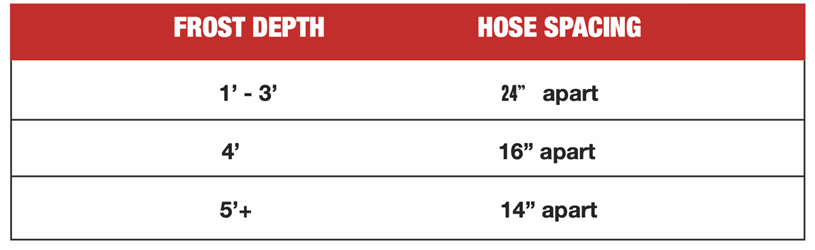

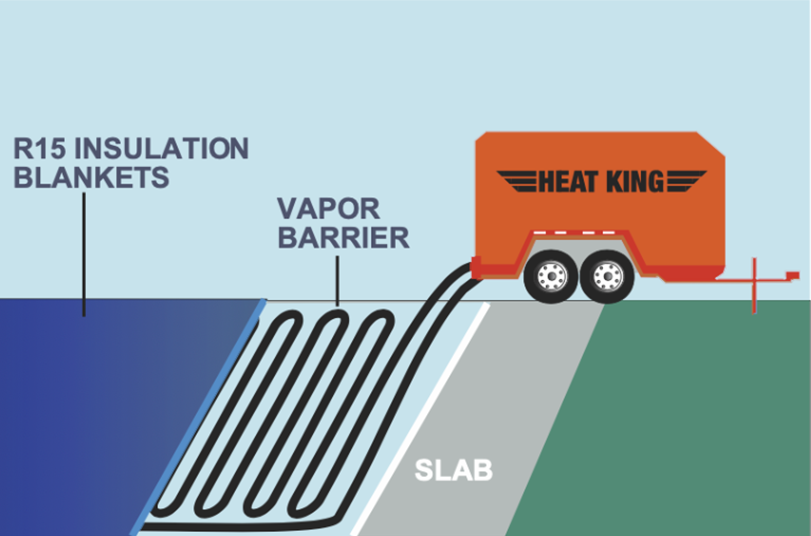

When beginning the process, use traditional, mechanical methods like snow plowing and shoveling to clear as much snow and frost as possible from the surface of the area to be thawed. This may not be the most pleasant process, but will be far quicker than waiting for a ground thawing system to melt its way through. With the surface clear and an accurate measurement of ground frost depth, the next step is to lay down a  polyethylene layer to act as a barrier for the water vapor to cover the work area, this will dramatically reduce the time needed to thaw the ground by trapping the water vapor and preventing heat from being dissipated. After this, it’s time to lay down the hoses from the heating system. In this chart by Heat King, the proper hose layout methods are displayed for many thawing applications.

polyethylene layer to act as a barrier for the water vapor to cover the work area, this will dramatically reduce the time needed to thaw the ground by trapping the water vapor and preventing heat from being dissipated. After this, it’s time to lay down the hoses from the heating system. In this chart by Heat King, the proper hose layout methods are displayed for many thawing applications.

The layout will be different for each application based on these factors, but anytime ground thaw equipment is involved, it is recommended to use the full available length of hose, even if covering a small area in order to get the most efficiency from the equipment and save the most time.

Once the equipment is set up and the hose is laid out, the next step is to lay insulation over the hoses. The best way to do this is to use a high-quality poly-clad insulation blanket. Once the thawing process is started, it’s important to let the process continue until all the frost has been melted so that the water can safely drain properly into the ground.

Concrete Curing

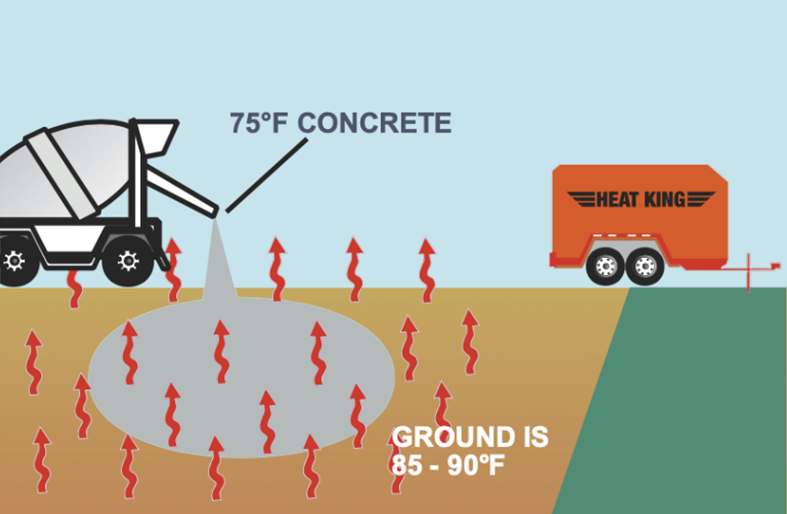

Now that we’ve covered ground thawing, we can also look at another important application of heating equipment, which is aiding in the concrete curing process. Concrete will only cure properly with heat, further increasing the challenge of wintertime work. If the concrete is too cold, it won’t cure, but if it becomes too hot, then it can lose essential moisture and the curing process will come to a halt. Ground thawing gear  like the HK300 from Heat King and the TCH250 from Thawzall can help with this too, both helping warm the ground before laying concrete, and keeping the concrete warm while curing.

like the HK300 from Heat King and the TCH250 from Thawzall can help with this too, both helping warm the ground before laying concrete, and keeping the concrete warm while curing.

As shown in the graphic here, there are ways to utilize heating equipment to keep the concrete warm while curing, and settings on the heat system can ensure that the concrete does not get too hot and lose moisture.

The numerous applications of ground thaw equipment are especially important during the unpredictable weather conditions we face during harsh winters. With the knowledge of how these systems can be applied, we can prepare for any cold weather conditions nature might throw our way.

The numerous applications of ground thaw equipment are especially important during the unpredictable weather conditions we face during harsh winters. With the knowledge of how these systems can be applied, we can prepare for any cold weather conditions nature might throw our way.

Thank you for taking the time to read all about ground thawing! Hopefully you’ve learned something new or found valuable information here, visit us again soon at The Toolbox!